Tool and die

Tool and die Specification

- Frame Type

- Heavy Duty / Rigid

- Accuracy

- 0.01 mm

- Lubricating System

- Automatic / Manual

- Voltage

- 220V / 380V / 415V

- Power Rating

- 220 V / 415 V

- Motor Power

- 3 HP - 10 HP

- Drive

- Direct / Belt Driven

- Machine Type

- Tool and Die / Custom Die

- Production Capacity

- Up to 5000 Units/month

- Features

- High Durability, Precise Designing, Wear Resistance, Long Life

- Connectivity Options

- Digital Interface / Manual Controls

- Plastic Processed

- Applicable for Metal and Certain Plastics

- Control System

- PLC / Manual

- Frequency

- 50 Hz / 60 Hz

- Operating Temperature

- 0C - 50C

- Model No

- TD-2024

- Cooling System

- Water / Oil Cooled

- Noise Level

- <75 dB

- Product Type

- Tool and Die

- Technology

- CNC Machining, EDM, Milling, Turning

- Power Source

- Hydraulic / Mechanical

- Operating Type

- Manual / Semi-Automatic / Automatic

- Power

- 2 kW - 10 kW (Depending on Model)

- Pressure

- High Precision Tolerance

- Surface Treatment

- Polished / Heat Treated / Coated

- Dimension (L*W*H)

- Custom Built (As per Specification)

- Weight (kg)

- 50 kg - 2000 kg

- Color

- Metallic Grey / Custom Finish

- Usage & Applications

- Metal Forming, Stamping, Molding, Punching, Cutting

- Lead Time

- 4-8 Weeks (Depending on Complexity)

- Application Industry

- Automotive, Electronics, Consumer Goods, Aerospace

- Number of Cavities

- Single / Multi Cavity (Customizable)

- Material

- Tool Steel / Carbide / Stainless Steel

- Maintenance

- Easy to Disassemble and Maintain

- Finish

- Micro-finish Surface for Superior Part Release

- Hardness

- Up to 60 HRC

- Export Markets

- Worldwide

- Packaging

- Wooden Crate / Protective Wrapping

- Design Support

- CAD / CAM Design Assistance

- Interchangeability

- Standardized Parts for Easy Replacement

Tool and die Trade Information

- Minimum Order Quantity

- 100 Number

- Main Domestic Market

- All India

About Tool and die

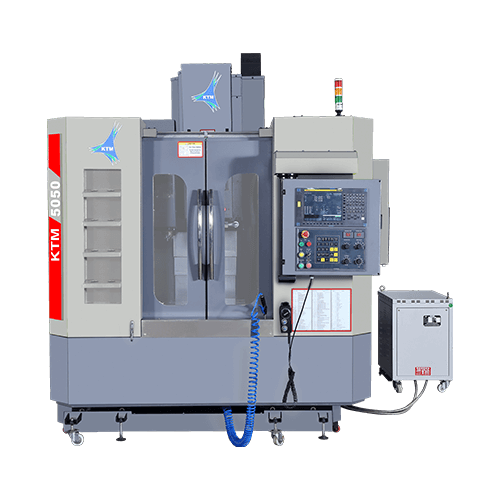

Eloquent Technology Services specializes in high-precision VMC (Vertical MachiningCenter) machining and tool and die manufacturing. Leveraging advanced machineryand cutting-edge technology, Eloquent Technology Services delivers top-quality,custom-engineered solutions for a wide range of industrial applications.

Applicationsof Eloquent Technology Services

- Aerospace Industry

- Precision components for aircraft engines and structural parts.

- Custom tools and dies for aerospace manufacturing processes.

- Automotive Industry

- Production of high-precision automotive parts and components.

- Custom tooling for manufacturing processes in the automotive sector.

- Medical Devices

- Machining of medical implants and surgical instruments with high precision.

- Custom dies for the production of medical device components.

- Electronics Industry

- Precision machining of components for electronic devices.

- Specialized tooling for the production of electronic parts.

- Defense Industry

- Manufacturing of precision components for defense equipment.

- Custom dies for defense manufacturing applications.

- General Manufacturing

- Custom machining for a wide range of industrial applications.

- Production of specialized tools and dies for various manufacturing processes.

Facilitiesfor Eloquent Technology Services

Machining Facility:

- CNC VMC Machines: Equipped with state-of-the-art CNC Vertical Machining Centers capable of high-precision machining.

- CAD/CAM Software: Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software for precise design and machining processes.

- Quality Control: Equipped with modern quality control equipment such as CMM (Coordinate Measuring Machines) to ensure precision and accuracy.

- Skilled Workforce: Highly trained machinists and engineers with expertise in VMC machining and tool and die manufacturing.

Tool and Die Manufacturing Facility:

- Tool Design and Development: In-house design team for developing custom tools and dies as per client requirements.

- Advanced Manufacturing Equipment: Latest machinery for tool and die manufacturing, VMC , Turning and grinding machines.

- Material Handling: Efficient material handling systems to ensure smooth workflow and timely delivery.

- Testing and Validation: Rigorous testing and validation processes to ensure the durability and functionality of tools and dies.

Eloquent Technology Services standsout for its commitment to quality, precision, and customer satisfaction, makingit a preferred partner for industries requiring high-precision machining andcustom tool and die solutions.

Eloquent Technology services for VMC(Vertical Machining Center) machining and Tool and Die manufacturing encompassa range of specialized services designed to enhance precision, efficiency, andproductivity in these areas. Here's a breakdown:

Precision Tool and Die Solutions

Utilizing materials like tool steel, carbide, and stainless steel, our tool and die products are crafted for exceptional wear resistance and precision. Designed with micro-finish surfaces and compatibility with high precision tolerance processes, these tools guarantee superior performance and easy maintenance in high-demand environments.

Advanced Manufacturing and Customization

From manual to fully automated operations, our dies are developed using state-of-the-art CNC machining, EDM, and other precision techniques. We support custom dimensions, cavity numbers, finishes, and power configurations to suit your specific requirements-backed by CAD/CAM design assistance for optimal project success.

Industries and Global Service Reach

Serving a vast range of industries such as automotive, electronics, consumer goods, and aerospace, we deliver both standard and bespoke tool and die solutions. With comprehensive export packaging and worldwide shipping, reliability and product safety are always ensured.

FAQ's of Tool and die:

Q: How can I customize a tool and die for my industry application?

A: You can specify material (tool steel, carbide, or stainless steel), number of cavities, finish, and size as per your project's needs. Our CAD/CAM design support team will assist you throughout the customization process to ensure suitability for automotive, electronics, consumer goods, or aerospace applications.Q: What is the typical lead time for manufacturing customized tool and die solutions?

A: Lead time ranges from 4 to 8 weeks, depending on the complexity of design, chosen materials, and specific production requirements.Q: Where are your tool and die products manufactured and shipped from?

A: All tools and dies are engineered and manufactured in India, and we export globally. Products are shipped safely in wooden crates with protective wrapping to ensure they arrive in perfect condition.Q: What processes are used in the manufacturing of these tool and die products?

A: The manufacturing process employs advanced CNC machining, EDM, milling, and turning. All operations are handled under strict quality control to maintain tight tolerances (0.01 mm) and high durability.Q: How does the maintenance and interchangeability of parts benefit my operations?

A: Standardized components allow for easy replacement and minimal downtime. The design also supports quick disassembly and maintenance for improved operational efficiency and reduced long-term costs.Q: What are the main advantages of using your tool and die solutions?

A: Advantages include high durability, wear resistance, precise designing, long operational life, and the ability to operate under rigorous conditions (up to 60 HRC hardness, high-pressure tolerance). Additionally, easy maintenance, customization, and worldwide shipping provide a significant operational edge.Q: What types of usage and applications are supported by your tool and die products?

A: They are ideal for metal forming, stamping, molding, punching, and cutting, and can be integrated into automated or manual production lines in diverse sectors. Applicable for processing metals and certain plastics, offering exceptional versatility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pellet Machine Category

Disc Pelletizer

Price 100 INR / Thousand

Minimum Order Quantity : 1 Number

Power Source : Other, Electric

Surface Treatment : Other, Paint Coated

Usage & Applications : Pelletizing ore, fertilizer, chemicals, cement

Operating Type : Automatic

Laboratory Hydraulic Pellet Press Machine

Price 500000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Power Source : Other, Electric

Surface Treatment : Other, Powder Coated

Usage & Applications : Laboratory sample preparation, pellet pressing for XRF, IR analysis

Operating Type : Other, Manual & SemiAutomatic

UV Machine

Price 300000.0 INR

Minimum Order Quantity : 1

Power Source : Other, Electric

Surface Treatment : Other, Powder Coated

Usage & Applications : UV Curing for Printing, Coating, Adhesive and Electronics

Operating Type : Automatic

Manual Hydraulic Pellet Press

Price 100 INR / Thousand

Minimum Order Quantity : 1 Number

Power Source : Other, Manual (Hydraulic Lever Operation)

Surface Treatment : Other, Rustresistant powder coating

Usage & Applications : Pellet preparation for laboratory analysis, FTIR sample pressing, analytical chemistry

Operating Type : Manual