Rotary slurry sample divider

Rotary slurry sample divider Specification

- Measurement Range

- Slurry Flow Rate up to 50 L/min

- Temperature Range

- Ambient

- Voltage

- 220V

- Feature

- High Splitting Accuracy, Easy Cleaning, Adjustable Splitting Ratio

- Frequency

- 50 Hz

- Capacity

- 5 L/min to 50 L/min (customizable)

- Automation Grade

- Semi-Automatic

- Model No

- RSSD-05

- Accuracy

- 1.5%

- Core Components

- Rotary Motor, Dividing Chamber, Collection Bins

- Power Source

- Electric

- Equipment Materials

- Stainless Steel (SS304/SS316 contact parts)

- Type

- Rotary Slurry Sample Divider

- Usage

- Laboratory and Industrial Slurry Sampling

- Display Type

- Analog

- Dimension (L*W*H)

- 650 x 450 x 900 mm

- Weight

- Approx. 65 kg

- Sample Particle Size Range

- Up to 8 mm

- Protective Features

- Overload protection, Splash Guard

- Number of Collection Bins

- 2 to 8 (as per requirement)

- Motor Power

- 0.5 HP

- Noise Level

- < 60 dB

- Inlet Connection Size

- DN25 or as specified

- Sampling Method

- Rotary Dividing Drum

- Surface Finish

- Polished Stainless Steel

- Minimum Split Ratio

- 1:2 to 1:8 adjustable

Rotary slurry sample divider Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 1 Months

About Rotary slurry sample divider

Power

Power 1.1. kw,/1.5 Hp

1.500kw / 2 Hp

Electrical Details

420 V /3,50Hz,4 pole,5 Amps

,

Material of construction

S.S agitation slurry tank, Agitator blade, Sample collection chutes

Feeding concentration Range

Feed Size

5 to 40 % solids

2 mm

Sample splitting

4 to 8 Splits in various combinations

Application Example

Glass Industry

Chemistry

Geology and mineralogy

Mining and Metallurgy

Ceramic Industry

Rock and soils

Advanced Rotary Dividing Mechanism

The RSSD-05 utilizes a rotary dividing drum to achieve high splitting accuracy, offering a minimum split ratio from 1:2 up to 1:8. This method ensures consistent and homogenous sampling, critical for reliable laboratory or industrial analysis. The semi-automatic design allows precise adjustment of sampling parameters, adapting seamlessly to various sample requirements.

Durable and Hygienic Design

Crafted from polished stainless steel (SS304/SS316 contact parts), the sample divider remains resistant to corrosion and easy to clean. The splash guard and overload protection increase safety during operation. Suitable for environments requiring stringent hygiene standards, the RSSD-05 supports ambient temperature conditions and operates smoothly with minimal noise (<60 dB).

Flexible and Customizable Sampling Capacity

With the ability to handle slurry flow rates from 5 to 50 L/min and accommodate sample particle sizes up to 8 mm, this equipment is versatile for both laboratory and industrial usage. The number of collection bins can be customized (2 to 8) to match specific testing needs. Users benefit from adjustable split ratios and clear analog display for optimal monitoring.

FAQ's of Rotary slurry sample divider:

Q: How does the rotary dividing drum enhance sample accuracy in slurry division?

A: The rotary dividing drum ensures uniform distribution of the slurry into collection bins, minimizing bias and achieving high splitting accuracy within 1.5%. The continuous rotary motion allows precise control over split ratios, which can be adjusted from 1:2 to 1:8, supporting reliable analytical results.Q: What are the main benefits of using the RSSD-05 in laboratory and industrial settings?

A: The RSSD-05 offers adjustable split ratios, multiple collection bins, and robust stainless steel construction, making it suitable for a wide range of slurry sampling tasks. Its protective features (overload protection, splash guard) ensure safe operation, while easy cleaning helps maintain consistent sample integrity across diverse environments.Q: When should the number of collection bins be customized, and how is this achieved?

A: Customization of collection bins (from 2 to 8) is recommended based on specific testing or analysis protocols. Bin quantity can be specified when ordering the equipment, allowing tailored sample division to meet particular research or industrial requirements.Q: Where can the rotary slurry sample divider be installed and used?

A: The RSSD-05 is designed for laboratory benches and industrial workplaces due to its compact dimensions (650 x 450 x 900 mm) and sturdy build. Its polished stainless steel surface resists corrosion, making it suitable for wet or harsh environments typically encountered in slurry analysis.Q: What is the typical process for operating the RSSD-05 sample divider?

A: Operators connect the slurry inlet (DN25 or as specified), set the desired split ratio and bin quantity, then start the semi-automatic rotary motor. The slurry is evenly divided into bins as the drum rotates. The analog display monitors key operational parameters, and post-processing cleaning is straightforward due to the smooth stainless steel design.Q: How does overload protection contribute to safe usage of the sample divider?

A: The RSSD-05's overload protection shuts down the rotary motor in case of excessive load or particle blockage, preventing equipment damage and ensuring operator safety. This feature is critical for minimizing unplanned downtime during high-volume or continuous sampling operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Riffle Sample Divider Category

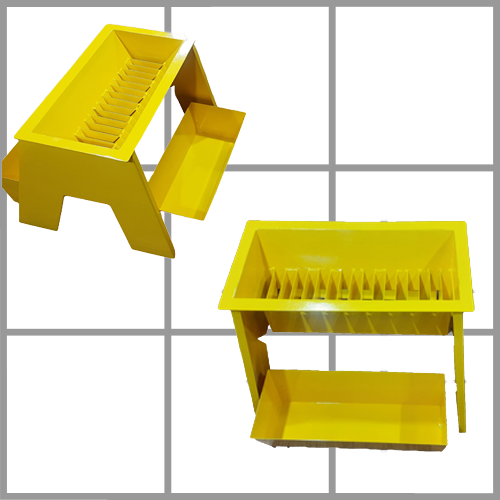

Riffle Sample Divider

Price 300000.0 INR

Minimum Order Quantity : 1

Usage : For accurate division and sampling of granular/powdered materials in laboratories or field

Type : Manual Sample Divider

Equipment Materials : Mild Steel/Stainless Steel

Accuracy : Ensures even and unbiased sample splitting

Manual Core Splitter

Price 300000.0 INR

Minimum Order Quantity : 1

Usage : Splitting rock core samples

Type : Core Splitter

Equipment Materials : Heavyduty steel frame, hardened steel splitting blades

Accuracy : High core splitting precision

3 - Tier riffle sample divider

Price 400000.0 INR

Minimum Order Quantity : 1

Usage : Laboratory and field sample division for grains, powders, and granular materials

Type : Riffle Sample Divider

Equipment Materials : Mild Steel with Powder Coating

Accuracy : 1% of sample mass per division

Riffle Sample Splitter

Price 45000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Riffle Splitters are perfect for precision splitting . depending on materialMild Steel Standard

Type : Sample Splitter

Equipment Materials : Stainless steel/ MS powder coated