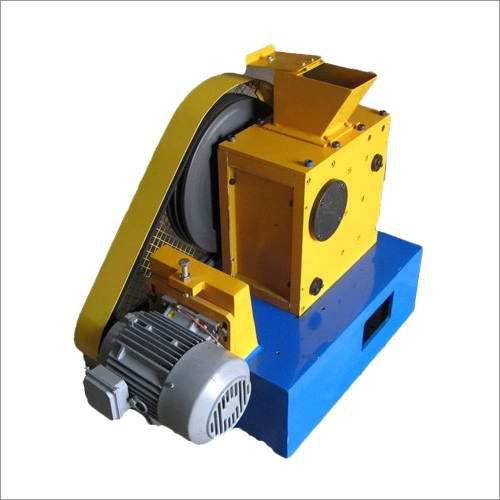

Crusher Roller

Crusher Roller Specification

- Rotation

- Bi-directional or Single Direction

- Model

- Standard / Custom Model

- Product Type

- Crusher Roller

- General Use

- Stone Crushing, Ore Crushing, Aggregate Processing

- Material

- High Manganese Steel / Alloy Steel / Cast Iron

- Type

- Industrial Roller

- Capacity

- 1-100 TPH (Depends on model & application)

- Weight (kg)

- 500-5000 Kg (Approx., depends on model)

- Computerized

- No

- Automatic

- Semi-Automatic / Manual

- CNC Or Not

- Not CNC

- Control System

- Manual

- Floor Space

- Custom / As per capacity

- Spindle Speed

- Approx. 20-60 RPM (Varies by model)

- Power

- Typically 5-30 HP (Varies by size & model)

- Voltage

- 220-440 V (Three Phase)

- Dimension (L*W*H)

- Custom / As per capacity

- Feature

- High Durability, Corrosion Resistance, Heavy Duty Performance

- Color

- Grey / As Required

- Roller Diameter

- 200-1200 mm (As required)

- Compatibility

- Fits various crusher machines as per configuration

- Application Industry

- Mining, Cement, Construction, Ceramic, Refractories

- Replacement Interval

- Subject to Usage/Material Processed

- Operating Temperature

- -20°C to +80°C

- Mounting Type

- Horizontal Mounting

- Working Speed

- Varies with application/type

- Structure

- Solid Roller with Knurled/Flat Surface

- Roller Length

- 300-2000 mm (Customizable)

- Noise Level

- Low

- Hardness

- 50-60 HRC (Depending on material)

- Surface Treatment

- Polished / Painted / Heat Treated

Crusher Roller Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 10 Per Day

- Delivery Time

- 7 Days

About Crusher Roller

Eloquent labaratory roll Crusher (or Roller Crusher) is used for middle crushing and fine crushing of all kinds of ores and rocks under mid-hardness range.This will be used in several industry liike mine, chemical industry, cement, building materials and other industrial sections.Tailored Engineering for Heavy Industries

Our crushers are purpose-built for intensive sectors including mining, cement, and construction. With a customizable structure-from roller size to surface finish-these rollers support a broad range of aggregates and ores, ensuring efficiency and reliability for demanding production needs.

Durability and Precision-Built In

Advanced surface treatments like polishing, painting, and heat treatment extend roller life and reduce downtime. High-grade materials confer hardness levels of 50-60 HRC, delivering heavy-duty performance with superior corrosion resistance and minimized maintenance.

Flexible Integration and Operation

The crusher rollers are compatible with various crusher machines and can be tailored for floor space, mounting type, and power requirements. Choose from standard or custom models to meet capacity demands ranging from 1-100 TPH, benefitting from low-noise, stable operation, and easy manual control.

FAQ's of Crusher Roller:

Q: How is the surface of the crusher roller treated to enhance performance?

A: The crusher rollers receive surface treatments such as polishing, painting, or heat treatment, which increase resistance to wear, corrosion, and harsh working conditions commonly faced in mining and construction.Q: What applications are these industrial rollers suitable for?

A: These rollers are versatile and designed for industries like mining, cement, construction, ceramics, and refractories, supporting tasks such as stone and ore crushing as well as aggregate processing.Q: When should the crusher roller be replaced?

A: Replacement intervals depend on the type of material processed and operating conditions. Regular inspections are recommended, especially in high-wear environments, to maintain optimal performance.Q: Where can these crusher rollers be installed?

A: They are designed for horizontal mounting and can be integrated into various crusher machines, adapting to custom floor space and capacity requirements as per industry standards.Q: What is the process for customizing roller dimensions and capacity?

A: Customers can specify roller diameter (200-1200 mm), length (300-2000 mm), and required throughput (1-100 TPH). The manufacturing team then adjusts material selection, surface treatment, and mounting configuration to match operational needs.Q: How do these rollers enhance operational benefits compared to alternatives?

A: With high durability, corrosion resistance, and heavy-duty construction, these rollers deliver reliable stone and aggregate crushing at low noise levels. This reduces maintenance costs, boosts output consistency, and ensures longevity even under challenging conditions.Q: What are the advantages of the manual or semi-automatic control system?

A: Manual and semi-automatic controls offer greater flexibility on site, making setup, speed adjustments, and maintenance straightforward and efficient-ideal for operations that require adaptability and low complexity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crushing Machine Category

Hammer Mill

Price 400000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Hammer Mill

Automatic : Other, SemiAutomatic

Feature : Other, Robust construction, low maintenance

General Use : Grinding and Pulverizing materials

Saw Core cutter

Price 400000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Core Cutter

Automatic : No

Feature : Other, Heavy Duty, Durable, Precision Cutting (No computerization)

General Use : Core cutting and drilling of concrete, stone, masonry

Hydraulic pellet press

Price 400000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Hydraulic Pellet Press

Automatic : Other, Manual/Automatic options available

Feature : Other, Robust construction, easy to operate

General Use : Used for pressing powdered materials into pellets

Laboratory Jaw Crusher Machine

Price 225000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Jaw Crusher Machine

Automatic : Yes

Feature : High Performance, High Efficiency

General Use : Industrial